Ethtec Process

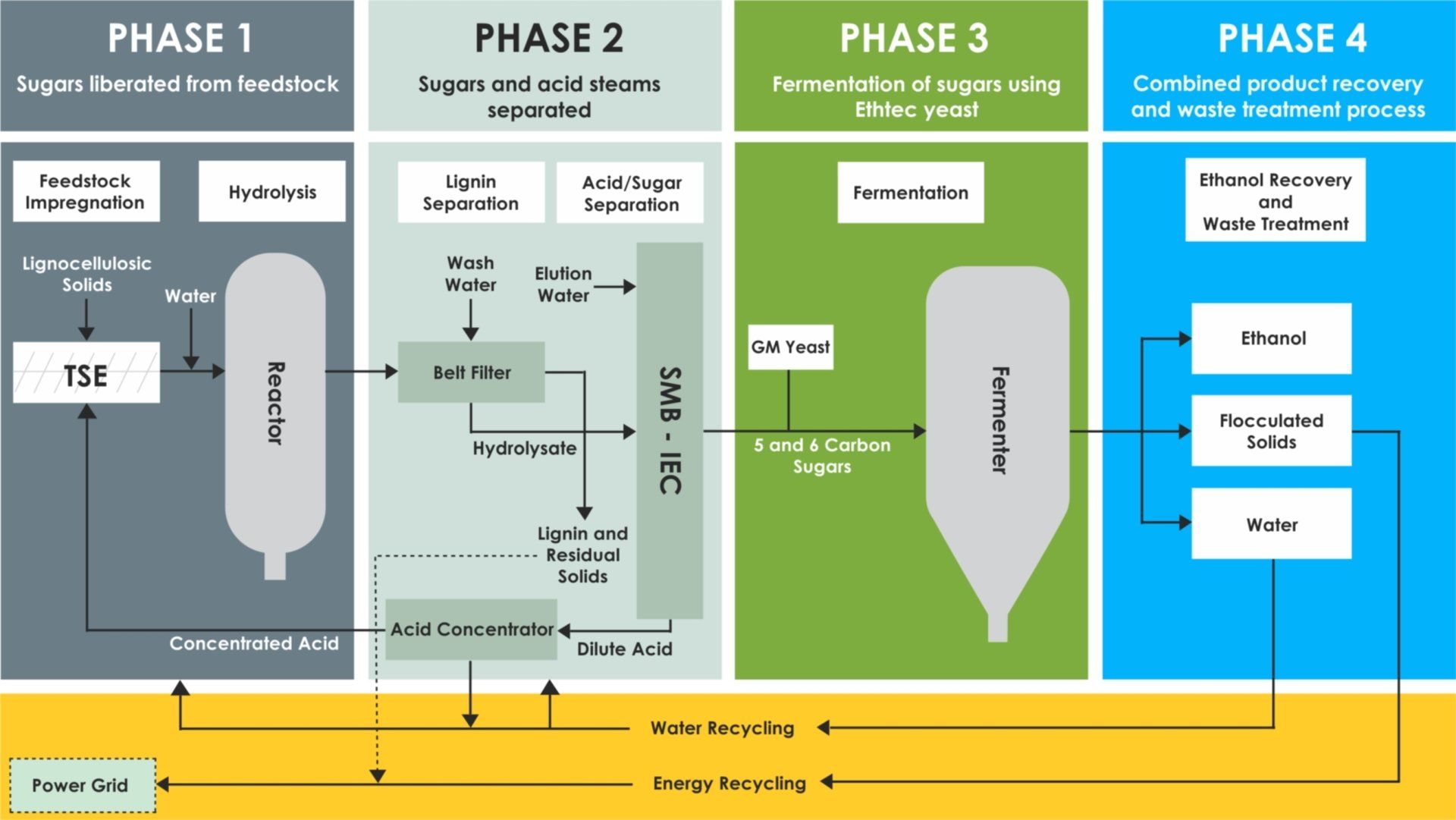

The Ethtec Process is divided into four phases:

Phase 1

– The lignocellulosic feedstock is firstly granulated and dried before being impregnated with concentrated sulphuric acid using a twin screw extruder (TSE). The extruder output (termed extrudate) is diluted with water before being reacted under temperature and pressure to liberate the feedstock structural sugars into solution.

The output of Phase 1 is a slurry consisting of acid and sugar in solution and solid lignin.

Phase 2

– The slurry is pumped into a continuous press filter where the solid lignin is removed. The lignin is used as a fuel to generate the steam and electricity required to drive the process. The clarified acid/sugars solution enters a simulated moving bed chromatography system (SMB) which separates the acid from the sugars. The acid is reconcentrated and recycled to the start of the process.

The output of Phase 2 is a concentrated acid stream and a fermentable sugars stream that is free of common fermentation inhibitors such as acetic acid, furfural, HMF and levulinic acid.

Phase 3

– The sugars stream, which is a mixture of glucose, mannose and galactose (termed 6 carbon sugars) along with xylose and arabinose (termed 5 carbon sugars), is fermented to ethanol or other high-value product(s) using genetically modified (GM) yeast capable of fermenting both 5 and 6 carbon sugars.

The output of Phase 3 is a fermentation broth containing the fermentation product(s) with little or no residual sugars.

Phase 4

– The fermentation broth enters a novel combined product recovery and waste treatment process. This process is expected to have significant energy savings compared with standard distillation and waste treatment techniques.

The output of Phase 4 is ethanol or other fermentation product(s). There are no associated liquid effluent or solid waste streams requiring disposal.

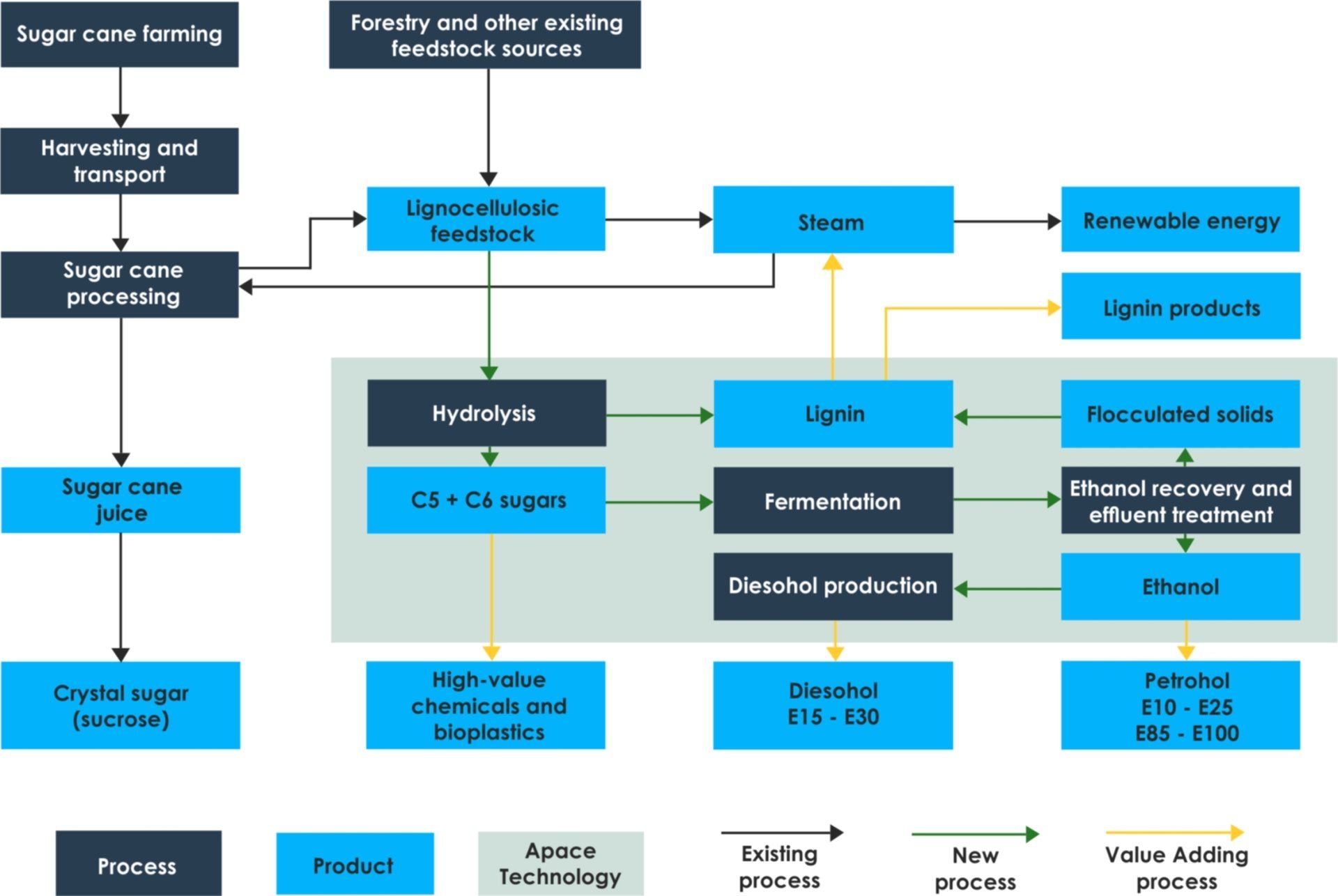

Integration of Ethtec Process with Existing Biomass Processing Operations

The Ethtec Process can be integrated with the existing framework of the sugar, forestry and other rural industries to optimise benefits from waste elimination, value-adding and vertical integration. The figure below illustrates how the Ethtec Process can be integrated with an existing sugar cane milling process, forest growing or timber milling process, without interfering with the production of traditional crystal sugar or sawn timber products, respectively.